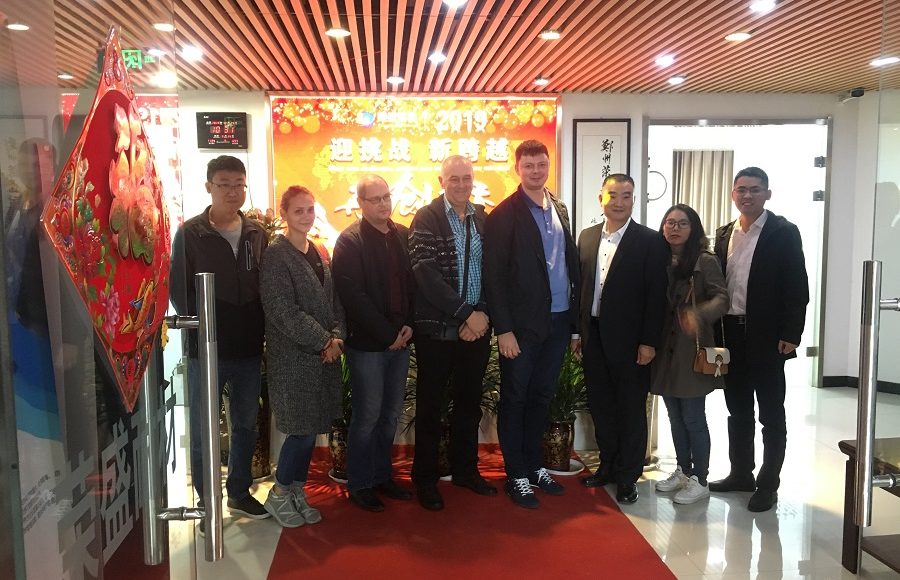

On October 24, 2019, several Russian customers came to Rongsheng, and they needed coke oven bricks. The cause of the damage of the coke oven lining is thermal stress and mechanical wear, and chemical erosion is also one of the causes of damage to the lining. Therefore, the refractory materials commonly used in coke ovens are silica bricks, magnesia bricks, high alumina bricks and clay bricks, among which silicon bricks have the largest amount and the best effect.

Coke Oven Refractories’ Requirement From Russia Customer

Silica brick is an acidic refractory material with good acid corrosion resistance. It has good thermal conductivity and high load softening temperature, generally above 1620 °C, only 70~80 °C lower than its refractoriness. The thermal conductivity of silica brick increases with the increase of working temperature, and there is no residual shrinkage. During the oven process, the volume of silica brick increases with the increase of temperature. Therefore, silica bricks are ideal refractory products on coke ovens. Important parts of modern large and medium-sized coke ovens (such as combustion chambers, chutes and regenerators) are constructed of silicon bricks.

In addition, Zhengzhou Rongsheng Refractory Co., Ltd. also supplies magnesia bricks, carbon bricks, high alumina bricks, clay bricks, corundum bricks, mullite bricks, spinel bricks, etc. If you have any requirement of refractory bricks or castables, now contact us, we will reply to you latest offer within 24 hours, and there is a discount!