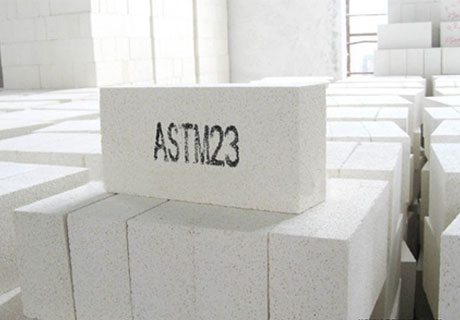

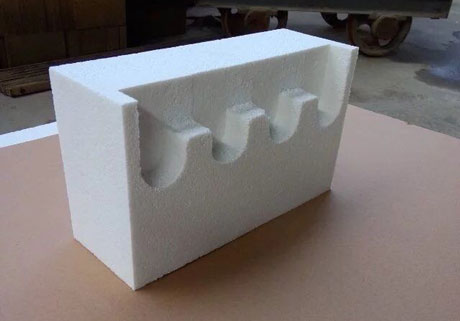

Brief Description

Refractory diatomite insulating brick blending the porous diatomite, which is the main raw material with alittle bonding clay, and agitate them to make the pug, and molding, drying, and firing, them the diatomaceous heat insulation a kind of heat insulation material that is widely used in various industrial kilns and thermal piping, te safe operation temperature is 900diatomite insulating brick can be formed by extrude machine and thencut into pieces by steel wire. Diatomite insulating brick can also shaped by plastic method. It can be cut into the exact size you need after itfired.

Technical Datas

| Products Properties |

FR-0.5 | FR-0.6 | FR-0.7 | FR-0.8 | FR-1.0 |

| Bulk density g/cm3 | ≤ 0.5 | ≤ 0.6 | ≤ 0.7 | ≤ 0.8 | ≤ 1.0 |

| Cold crushing strength kg/cm2 | ≥ 8 | ≥ 12 | ≥ 20 | ≥ 35 | ≥ 50 |

| Reheat shrinkage % at 900° C× 8hrs | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 |

| Thermal conductivity W/(M. K)at 300° C mean | 0.11 | 0.15 | 0.18 | 0.20 | 0.23 |

| Max service temp ° C | 900 | 900 | 900 | 900 | 900 |

| Chemical composition % SiO2 Al2O3 Fe2O3 |

|||||

| 71.5 | 71.0 | 70.5 | 70.0 | 70.0 | |

| 16.5 | 17.0 | 17.5 | 18.0 | 18.0 | |

| 4.0 | 4.2 | 4.5 | 5.0 | 5.0 | |

Application

Strong adsorbability/ light weight /sound insulation /wear resistance /high temperature resistance/ acid resistanceapplication: Diatomite insulating brick is largely used in the tunnel kilnsand various furnaces where the thermal insulation is needed.

It is mostly applied heat preservation of pipeline transportation equipments of the gas and the liquid in electric power, metallurgy, engineering, chemical industry, petroleum industries etc. Also, it is used to the thermal protective coating of high temperature pyrology equipment within electric furnace, heating furnace, steel furnace, annealing furnace, and glass furnace etc.