Zeolite runner adsorption concentration + RTO treatment process is currently the mainstream technology for treating low concentration and large air volume in organic waste gas treatment. Since the direct combustion of low-concentration waste gas using the RTO waste gas treatment process requires a large amount of fuel such as natural gas to be supplemented, the operating cost is high and it is not economically cost-effective. Therefore, it is necessary to condense the low-concentration waste gas and turn it into high-concentration waste gas for combustion, which saves energy and reduces the size of the equipment.

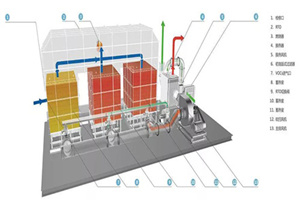

The treatment process is divided into adsorption stage, desorption stage, RTO combustion stage and zeolite runner recovery stage.

Adsorption stage: The organic waste gas is directly discharged after being adsorbed by the zeolite runner. Due to the pore size of the zeolite molecular sieve, it can selectively adsorb according to the size and polarity of the exhaust gas molecules. Even if the concentration of the exhaust gas components is very low, it has a high Adsorption capacity.

Desorption stage: The zeolite runner always keeps rotating very slowly. The exhaust gas treatment zone is adsorbed and saturated, and the organic waste gas adsorbed in the zeolite is desorbed by hot air in the regeneration zone.

RTO combustion stage: The zeolite runner is actually a concentration device, which captures and concentrates the exhaust gas molecules in the low-concentration and high-volume exhaust gas on the zeolite. When desorbed, the exhaust gas molecules can be swept from the zeolite with a small amount of hot air. The high-concentration and low-volume exhaust gas from the desorption can directly enter the RTO regenerative incinerator for high-temperature incineration, and the device is the same as the aforementioned RTO incineration device.

The recovery stage of the zeolite runner: after high temperature regeneration in the desorption zone of the zeolite runner, the temperature of the zeolite will be very high, which will make the adsorption effect worse. Therefore, the temperature of the zeolite area that has been purged at high temperature should be cooled with a supplemental cooling fan. The cooled zeolite has the ability to adsorb exhaust gas, and cyclically adsorb exhaust gas again and again.