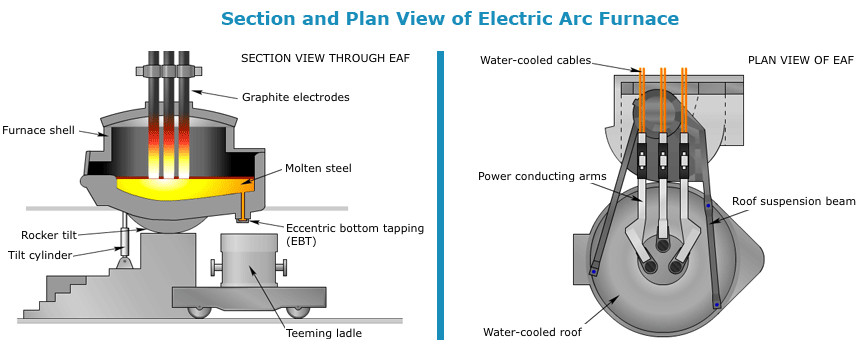

Brief Description Of Graphite Electrode

The graphite electrode will be a high-temperature graphite conductive material, the core of which consists of petroleum coke, tar coke as a filler, coal tar as a binder. We produce and sell graphite electrodes and nipples to them. According to its high quality and low quality, it can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode.

The main raw material for graphite electrode production is petroleum coke. The ordinary power graphite electrode can be added with a small amount of pitch coke. The sulfur content of petroleum coke and pitch coke cannot exceed 0.5%. Needle coke is also required for the production of high power or ultra high power graphite electrodes. The main raw material for aluminum anode production is petroleum coke, and the control sulfur content is not more than 1.5% to 2%. Petroleum coke and pitch coke should meet the relevant national quality standards. Any interests for our graphite electrode, pls email us for more information :inquiry@rsrefractorygroup.com

Classification

Application

Technical Characteristics

| Name | Unit | Nominal Diameter | ||||||

| UHP Ultra-High-Power | HP Superstrong | RP Conventional Power | ||||||

| ≤Φ400 | ≥Φ450 | ≤Φ400 | ≥Φ450 | ≤Φ300 | ≥Φ350 | |||

| Resistivity | Electrode | ΜΩ · m | ≤5.5 | ≤6.5 | ≤8.5 | |||

| Nipple | ≤4.5 | ≤5.5 | ≤6.5 | |||||

| Flexural Strength | Electrode | MPa | ≥11.0 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

| Nipple | ≥20.0 | ≥16.0 | ≥15.0 | |||||

| Elastic Modulus | Electrode | GPa | ≤14.0 | ≤12.0 | ≤9.3 | |||

| Nipple | ≤18.0 | ≤16.0 | ≤14.0 | |||||

| Density | Electrode | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

| Nipple | ≥1.75 | ≥1.73 | ≥1.69 | |||||

| Coefficient Of Thermal Expansion | Electrode | 10-6 / ℃ | ≤1.5 | ≤2.4 | ≤2.9 | |||

| Nipple | ≤1.4 | ≤2.2 | ≤2.8 | |||||

| ASH | % | ≤0.3 | ≤0.3 | ≤0.5 | ||||

| Note: 1.Koeffitsient ash content and thermal expansion as the reference index, the coefficient of thermal expansion (100 ℃ ~ 600 ℃), Custom manufacturing. | ||||||||

| Name | Unit | Nominal Diameter (mm) | ||

| 300, 350, 400 | 450, 500 | |||

| Resistivity (not more than) | Electrode | ΜΩ · m | 6.2 | 6.5 |

| Nipple | 5.5 | 5.5 | ||

| Flexural Strength(not less than) | Electrode | MPa | 10.5 | 10 |

| Nipple | 16 | 16 | ||

| Elastic Modulus(no more) | Electrode | GPa | 14 | 14 |

| Nipple | 18 | 18 | ||

| Density(not less than) | Electrode | g / cm3 | 1.65 | 1.64 |

| Nipple | 1.72 | 1.7 | ||

| Coefficient Of Thermal Expansion (no more) | Electrode | 10-6 / ℃ | 1.5 | 1.5 |

| Nipple | 1.4 | 1.4 | ||

| Ash Content (not more than) | % | 0.3 | 0.3 | |

| Note: 1. Zonality as a reference index. | ||||

Diameter Available

For RP grade, the Diameter is usually 100 -1060MM.

For RPI grade, the Diameter is usually 200 -650MM.

For HP grade, the Diameter is usually 300-650MM.

For SHP grade, the Diameter is usually 400-650MM.

For UHP grade, the Diameter is usually 400-650MM.

Length & Diameter & Permissible Deviation

| Nominal Diameter | Actual Diameter | Length (mm) | Tolerance | ||||

| MM | Inch | Poppy | Mines | The Minimum Size Of The Black Part | Length | Short Length | |

| 75 | 3 | 78 | 73 | 72 | 1400/1600 | ± 100 | -275 |

| 100 | 4 | 103 | 98 | 97 | 1400/1600 | ||

| 130 | 5 | 132 | 127 | 126 | 1400 | ||

| 150 | 6 | 154 | 149 | 146 | 1400/1600/1800 | ||

| 175 | 7 | 180 | 174 | 172 | 1400/1600 | ||

| 200 | 8 | 205 | 200 | 197 | 1600/1800 | ||

| 225 | 9 | 230 | 225 | 222 | 1600/1800 | ||

| 250 | 10 | 255 | 251 | 248 | 1600/1800 | ||

| 300 | 12 | 307 | 302 | 299 | 1600/1800/2000 | ||

| 350 | 14 | 357 | 352 | 349 | 1600/1800/2000 | ||

| 400 | 16 | 409 | 403 | 400 | 1600/1800/2000/22000 | ||

| 450 | 18 | 460 | 454 | 451 | 1600/1800/2000/22000 | ||

| 500 | 20 | 511 | 505 | 502 | 1600/1800/2000/22000 | ||

| 550 | 22 | 562 | 556 | 553 | 1800/2000/2200/2400 | ||

| 600 | 24 | 613 | 607 | 604 | 2000/2200/2400/2700 | ||

| 650 | 26 | 663 | 659 | 656 | 2000/2200/2400/2700 | ||

| 700 | 28 | 714 | 710 | 707 | 2000/2200/2400/2700 | ||

When Connecting the Electrodes, Please Note

1. Please check the internal thread of the electrode first. If not intact, contact sales staff to confirm whether the electrode can work properly.

2. Please clean the electrodes with compressed air before connecting.

3.When the electrode is squeezed into the electrode hole at one end, the pad can be prepared at the other end to avoid nipple breakage.

4. Drop down slowly when the new electrode is directly above the hole connected to the electrode.

5. Put the insulator between the two electrodes, and the electrode drop slowly to prevent the electrode hole breakage and nipple threads.

6. Raise the new electrode slightly, and then remove the insulator, connect the two electrodes.

7. Tighten the electrodes with a proper wrench and specified torque