Brief Description

Calcium aluminate cement is a cement containing calcium monoaluminate (CaO·Al 2 O 3 ) or calcium aluminate (CaO·2Al 2 O 3 ) as the main mineral component. It is made of natural bauxite or industrial alumina and calcium carbonate (limestone) in a certain proportion, calcined or electrofused, and also made by mixing iron bauxite and limestone. Calcium aluminate cements are cements consisting predominantly of hydraulic calcium aluminates. Alternative names are “aluminous cement”, “high-alumina cement” and “Ciment fondu” in French. They are used in a number of small-scale, specialized applications

Composition and Classification

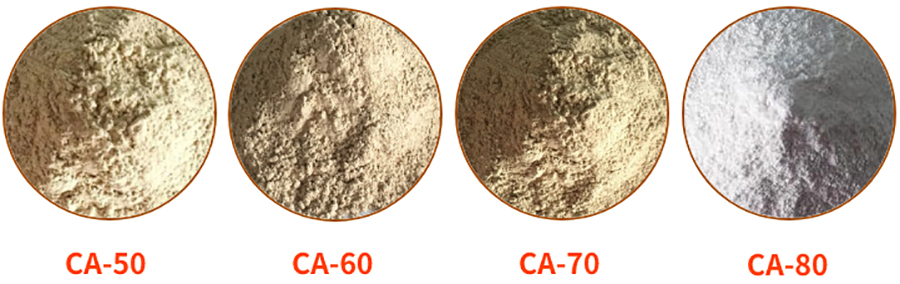

Calcium Aluminate Cement can be classified into two types of common calcium aluminate cement (Al2O3 53~72%,CaO 21~35%) and pure calcium aluminate cement (Al2O3 72~82%,CaO 19~23%) according to its chemical component . Common calcium aluminate cement also can be classified into two types of low iron content (Fe2O3<2%) and high iron content (Fe2O37~16%). Low iron type also can be classified into bauxite cement (Al2O3 53~56%,CaO 33~35%), Aluminum-60 cement (Al2O3 59%~61%,CaO 27~31%) and aluminate cement (Al2O3 65~70%,CaO 21~24%). Pure calcium aluminate cement can be classified into common type (Al2O3 72~78%) and ultrahigh aluminum type (Al2O3 78~85%)

Specifications

| Calcium Aluminate Cement | ||||||

| CA-65 | CA-68 | CA-70 | CA-75 | CA-80 | ||

| Chemical Composition (%) | Al2O3 | 64-66 | 67-69 | 69-71 | 73-75 | 77-80 |

| CaO | 32-34 | 29-31 | 27-29 | 23-25 | 18-20 | |

| SiO2 | 1.8 | 1.2 | 0.3 | 0.3 | 0.3 | |

| Fe2O3 | 0.6 | 0.6 | 0.3 | 0.3 | 0.3 | |

| Specific Surface (cm2/g) | 4500 | 4500 | 5000 | 5500 | 7000 | |

| Setting time (h:min) | Initial setting (min) | 0:40 | 0:40 | 0:40 | 0:45 | 0:45 |

| Final Setting (min) | 8:00 | 8:00 | 10:00 | 10:00 | 10:00 | |

| Cold Modulus of Rupture (MPa) | 24 hour | 6.0min | 6.0min | 6.0min | 6.0min | 5.0min |

| 72 hour | 8.0min | 8.0min | 8.0min | 8.0min | 6.0min | |

| Cold Crushing Strength (Mpa) | 24hour | 45.0min | 45.0min | 45.0min | 45.0min | 35.0min |

| 72hour | 70.0min | 70.0min | 70.0min | 70.0min | 60.0min | |

| Refractoriness (°C) | 1680 | 1710 | 1730 | 1750 | 1770 | |

Application

Calcium aluminate cement is mainly used in coke ovens, glass kilns, blast furnace hot blast furnaces, and other industrial kilns.Applied industries: metallurgy, building materials, machinery, petrochemical, glass, boilers, electricity, steel, cement, and so on.